Aluminum refining thermal vehicle plays a crucial role in alloy production, primarily removing oxide

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

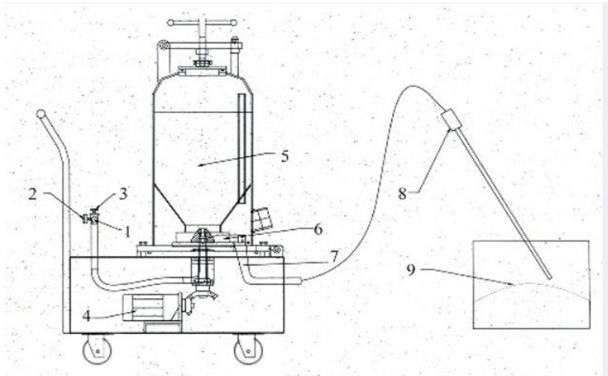

Working Principle:

Aluminum refining spraying vehicle plays a crucial role in alloy production, primarily removing oxides and other impurities from molten aluminum. It is termed a composite refiner because it utilizes a mixture of solid particulate refining agents and inert gas delivered into the molten aluminum via a powder injection tube. Operators continuously maneuver the tube to optimize refining efficiency.

Equipment Features:

Technical Specifications:

Application Scope:

Suitable for various pool-type aluminum melting furnaces.

Disclaimer: Il contenuto di cui sopra è per riferimento e comunicazione solo tra addetti ai lavori del settore e non garantisce la sua accuratezza o completezza. Secondo le leggi e i regolamenti pertinenti e i regolamenti di questo sito web, le unità o le persone fisiche che acquistano articoli correlati devono ottenere qualifiche e condizioni di qualificazione valide.

Telefono aziendale

+86-21-6420 0566

Orario di lavoro

Da lunedì a venerdì

Telefono cellulare:

13816217984

Posta elettronica:

info@qinsun-lab.com